- 2019.12.16

- The homepage has been redesigned.

Company movie

Narrator:Katsuaki Goto

Yamaguchi Seiki Kogyo supports the Sustainable Development Goals(SDGs).

4 Key strengths

State-of-the-art Technology and Equipment.

To be a manufacturing company challenging the world.

Creating molds backed by expertized design capability and well equipped shop.

Since the foundation in 1968, Yamaguchi Seiki Kogyo Co., Ltd. is a leading supplier of plastic injection molds, focusing on mold design and engineering for Automotive customers.

The strongest points of Yamaguchi Seiki Kogyo Co.,Ltd. are

both the sophisticated designers and engineers in the industry to have continuously been manufacturing high quality molds and

plants equipped with innovative machinery

to satisfying client’s requirement and expectation for Automotive idustry.

Within a single month, our current manufacturing facility enables us to build 6 sets of mold for 3000 tonnage, 6 sets of mold for 1600 tonnage, and 10 sets of mold for 850 or less tonnage .

To enhace the mold quality further, it is the in-house design ratio that is increased to over current 88% for a comming decade.

Ten years ago, Yamaguchi Seiki Kogyo purchased design drawings from outsourcing company. However, we have been educating and training our own staffs in-house and now the eighty eight percent of the business has been finalized by our expert mold designers and engineers.

Then, we are committed to serve customers more quickly and more reliable on our molds , responding to the design changing requirements from customers.

Highly qualified molds.

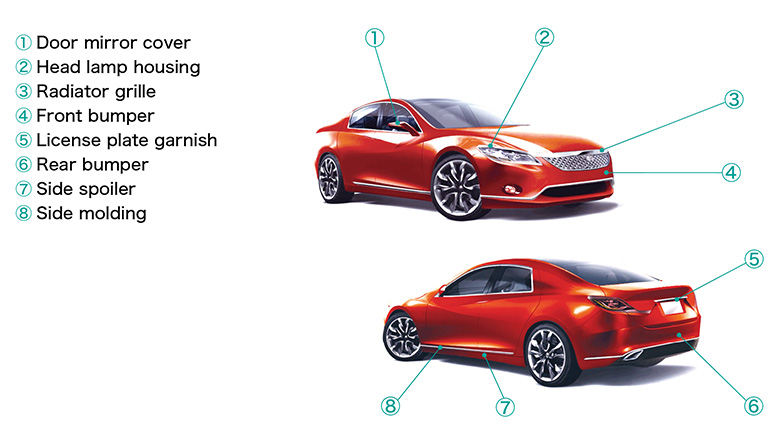

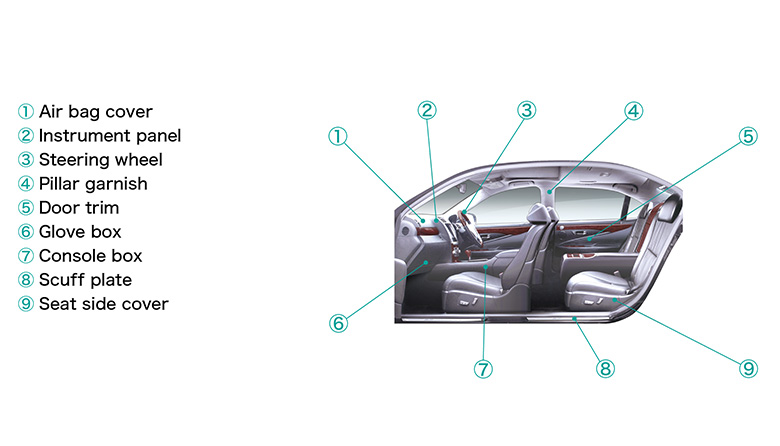

The reliability of Automotive parts born from mold by the Yamaguchi Seiki Molds.

Stable manufacturing capability.

Manufacturing capabilities and advantages

Monthly production《 Large mold advantages 》

- Large molds ranging 3000 tonnage class : 7molds

(5 molds for bumper, 2 molds for instrument panel) - Middle size molds ranging 1600 tonnage : 6 molds for door trim per month

- Small size molds ranging 850 or less tonnage : 10 molds per month

Facility Features

- In-house production of main stationary and moving molds and major internal cores

- Keeping plastic Injection molding machines to test in-house before shipping : 290,850,1600 and 3500 tonnage.

- Developing and applying 3D induction quenching equipment

- Keeping carriage type large Furnace which can elevate the temperature up to 550℃

Enhancing strong organization environment

by full participation of the workforce

Since 2006, as one of the company-wide actions to reinforce our vital quality and the reliability, we have been having ‘morning assembly’ to speak out with one voice ”Yaruzo call “(Strive for best) every morning and to inspire and motivate ourselves.

Since May 2007 we have started weekly Kaizen meeting as company-wide actions, and each department has briefed the result every Thursday for the purpose of sharing wisdom for expanding corporate capabilities in full participation.

For more details about Kaizen avtivity, visit the page;