Engineering Dept. (CAD Section / CAM Section)

The department plays the heart of the company organization directly governning the level of mold quality.

Engineering Dept. is organized with CAD and CAM section.

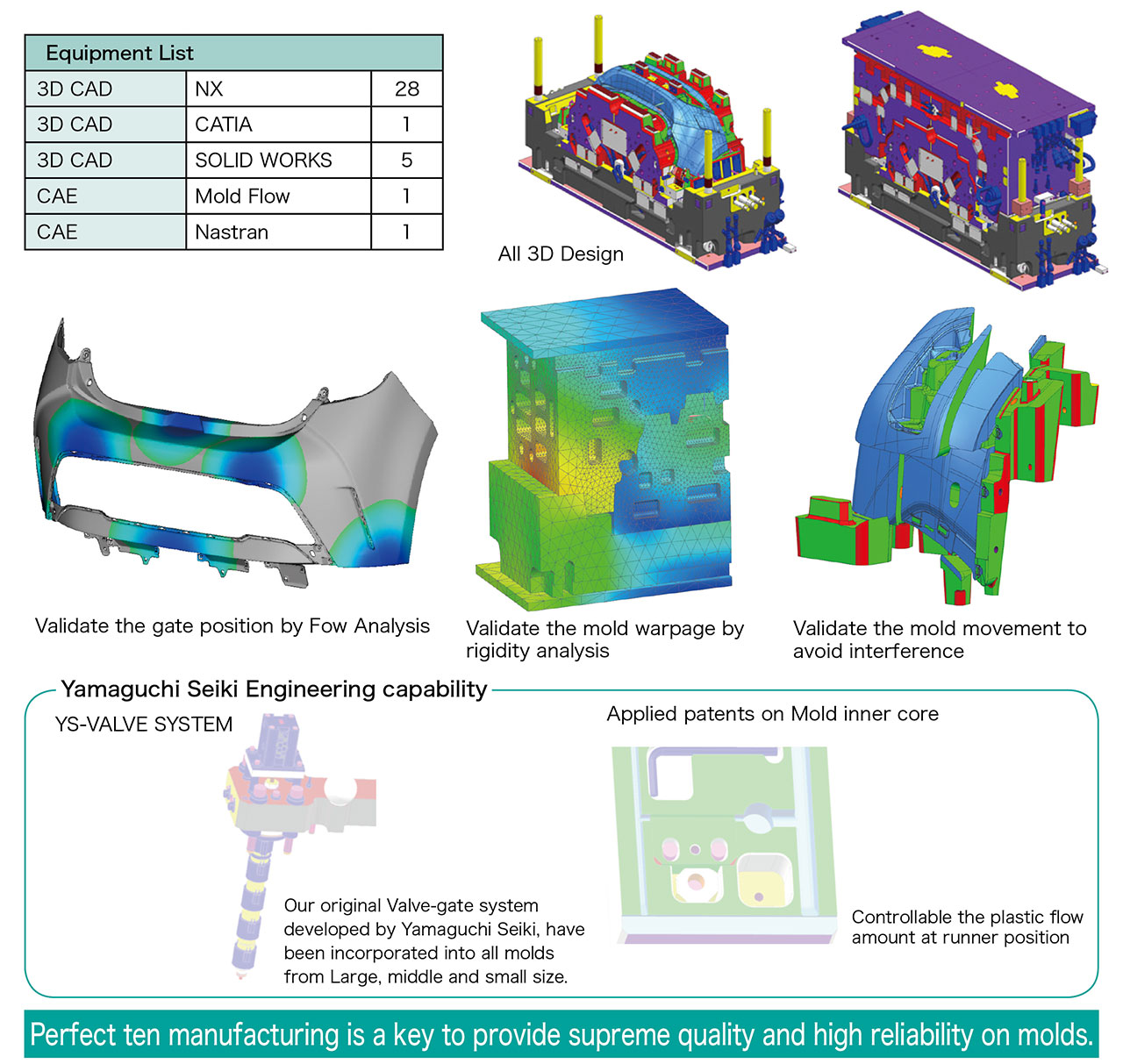

The department takes in charge of designing mold and mold component and generating numerical control data for machining.

CAD section takes all responsibilities of designing mold based on model-data of automotive parts our clients designed.

Mold Designing is the key factor to greatly affect the quality of mold itself.

Current members in CAD section are 20 engineers as full time workers.

One mold is taken the responsibility by one or two engineers . Bumper mold designing , for example, is required for 40 to 60 days from initial contact to it’s finished while making sure of what clients expect. The feature distinguished of the CAD section are to design with full-solid model system.

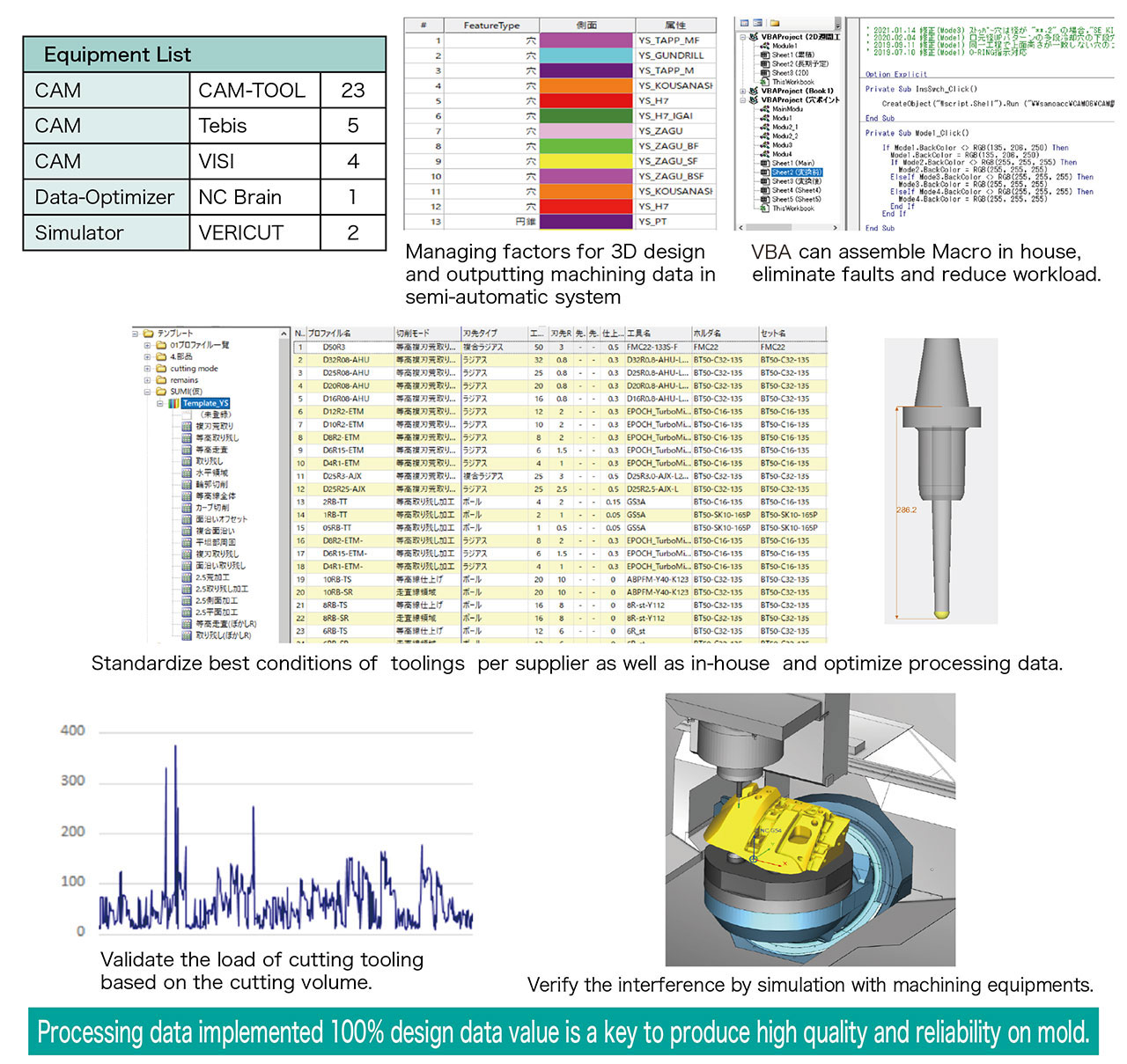

CAM section creates elaborate numerical control data for machining. Various types of machinery including EDM and wire-EDM will be chosen depending on the form and dimensions. It is the CAM section that accepts creation of all NC-data for maching.

To play a key role in creating next-era molds , corresponding to requirements from human and social changes.

The first phase to build mold starts from close discuccion with customers by sharing precise requirements and desire. Only such requirements and desire makes us plan and design mold to fully satisfy customers.

Engineering Dept., has a crucial role at the initial stage of mold building. For engineers ,the higher design capability as well as design sensibility are asked. Today, It is because technology and engineering is advancing and growing increasingly complex. The product around human and human life ,however, are reaquired a kind of warmth, tenderness and comfortableness favorable for human as well as the higher accurracy.

Then, we have been tackling to integrate the state-of-the-art engineering and know-how together with the human aspects of engineers such as flexibility to get solutions and conceptual breakthrough. We have no doubt such integration brings us true technical inovation in ‘Mold Industry’ and develops the new creation of ‘Mechanism’.